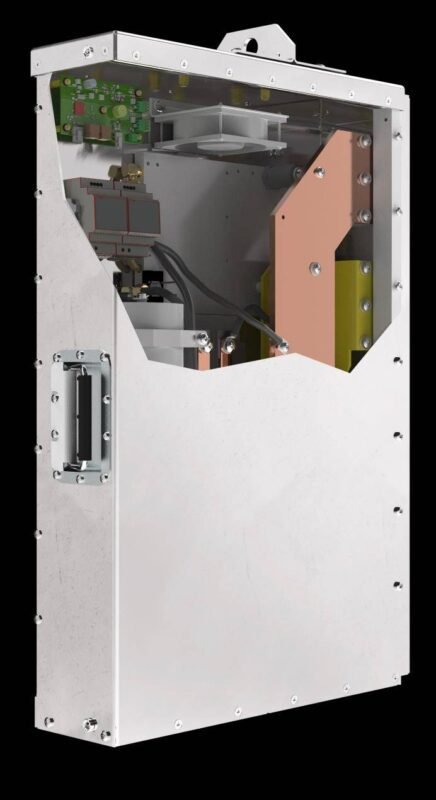

Saipem has recently unveiled an innovative safety solution called the LiSa Hyper Harness, aimed at improving worker safety on construction sites through the use of sensors and artificial intelligence. This advanced device actively checks that workers’ safety belts are securely fastened during high-altitude activities. If a safety issue arises—such as an incorrect connection—the harness triggers an audible alert akin to that of a car seat belt, ensuring that operators are immediately aware of any problems.

Beyond its acoustic warning system, the LiSa Hyper Harness also communicates real-time discrepancies to supervisors, facilitating swift intervention and assurance of the situation. This feature significantly enhances response times during critical incidents, thereby bolstering overall safety protocols. The harness is equipped with intelligent sensors connected to a centralized data platform, which continually gathers and evaluates information, ultimately aiming to enhance its effectiveness while fostering a safety-first culture among workers.

The development of this pioneering device involved collaboration with two Italian companies: Confezioni Mario De Cecco, specializing in personal protective equipment, and R13 Technology srl, an academic spin-off focused on technological innovations. The LiSa Hyper Harness is currently in production and will be gradually implemented across Saipem’s work sites as part of their Strategic Safety Plan, which emphasizes the well-being of personnel through training and proactive measures.

Looking ahead, Saipem is poised to extend the implementation of this groundbreaking solution beyond its own projects by collaborating with clients and stakeholders. The objective is to enhance safety measures for all activities conducted at height across various global industries.

Share it now