Subsea Global Solutions recently completed a complex in-water thruster installation and rudder bushing replacement, avoiding the need for drydocking and keeping the vessel on schedule. Originally planned for drydock, the repairs were accelerated to meet the vessel’s operational needs. The company was chosen for its expertise in in-water technical repairs and track record of successful projects for the client. The project took place in Portland, Oregon, with support from various Subsea Global Solutions locations across the country, including Long Beach, Port Angeles, Miami, and Houston.

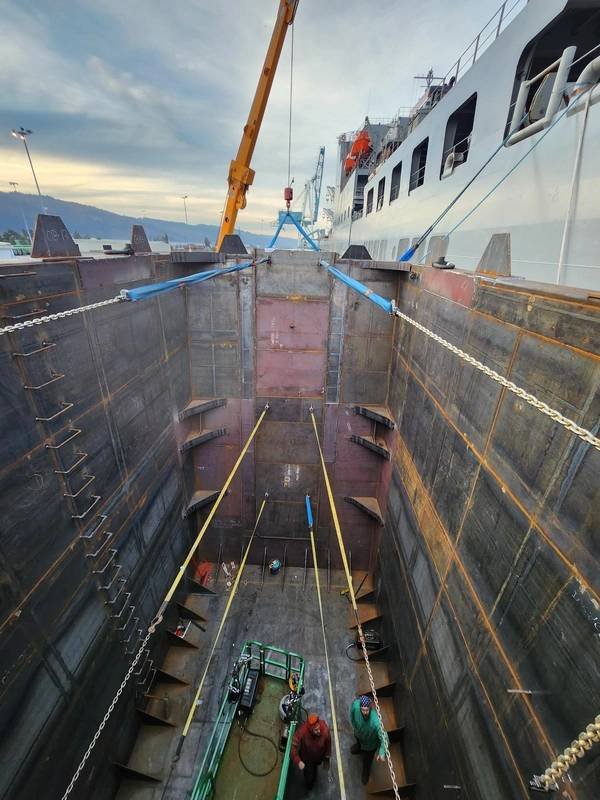

The operation involved round-the-clock shifts, with multiple teams working simultaneously on fabricating the cofferdam, installing the thruster, and replacing the rudder bushing. A crucial aspect of the repair was the engineering and fabrication of a custom reusable cofferdam to create a dry environment for the rudder bushing replacement. This massive cofferdam, weighing over 51 metric tons and generating 300 metric tons of buoyant force, fully enclosed the 43.5-metric-ton rudder, allowing for a precise and controlled repair. It is considered one of the largest cofferdams of its kind.

Despite facing challenging weather conditions, in-water currents, and limited visibility, Subsea Global Solutions’ expert dive teams successfully carried out the repairs with precision. This ensured that the vessel could resume service promptly and without any delays. The company’s ability to navigate through obstacles and execute the project efficiently showcases their commitment to providing high-quality in-water technical repairs for their clients.