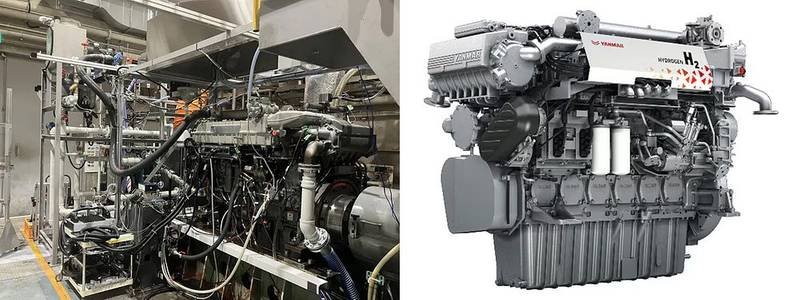

WinGD has received type approval for its on-engine NOx reduction solution, marking the first commercial deployment of this technology on engines. The integrated Selective Catalytic Reduction (iSCR) solution was tested at Mitsui E&S DU (MESDU) Co’s factory in Japan on three WinGD 5X52-S2.0 engines being built for bulk carriers. This milestone comes after more than two years of service experience with a prototype version, with the latest iteration featuring cost reductions, a heating unit for heavy fuel oil operation, and design changes to reduce ammonia slip.

According to WinGD Vice President Peter Krähenbühl, the on-engine NOx abatement solution ensures compliance with IMO Tier III regulations while offering operators more flexibility in engine room configuration and ship design. The new iteration further lowers the cost impact of NOx abatement and enhances treatment efficiency with various fuels. The iSCR technology simplifies piping requirements and testing, as the engine and NOx abatement system can be tested together before installation, while optimised exhaust flow management and waste heat from the engine contribute to effective treatment.

The test of the iSCR technology was witnessed by representatives from eight major classification societies, including ABS, BV, DNV, LR, and ClassNK. This technology is available as an option for WinGD’s 52- and 62-bore engines, with potential extension to other engines based on market demand. The solution not only reduces the footprint of off-engine equipment but also offers operational benefits such as simplified testing and commissioning processes.