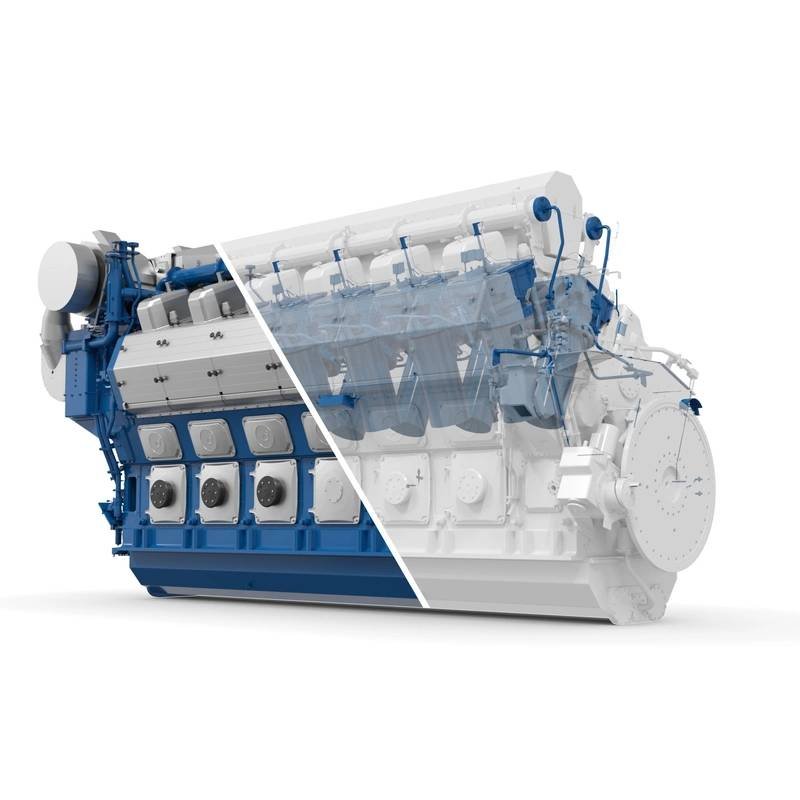

Wärtsilä has recently unveiled a methane slip reduction solution for its Wärtsilä 50DF dual-fuel engine. This innovative technology converts the engine to spark gas operation, resulting in a more efficient combustion process and reduced methane emissions. When operating on LNG, the conversion can lower methane emissions by up to 75% compared to the standard Wärtsilä 50DF engine.

The spark gas conversion works by introducing an electrically controlled pre-combustion chamber valve, which optimizes the combustion process and minimizes methane emissions. As a result, the new solution can reduce methane emissions to just 1.1% of fuel use on an IMO weighted average. Chevron has already committed to converting one engine on six of its LNG carriers to spark gas, as part of its efforts to reduce the carbon intensity of its operations.

This methane slip reduction solution is specifically designed for vessels with existing Wärtsilä 50DF engine diesel-electric propulsion, which are predominantly LNG carriers. By optimizing the engine for LNG fuel, the solution not only improves energy output per unit of fuel but also offers fuel gas savings of up to 4.6% while lowering methane emissions. This advancement represents a significant step towards more sustainable and environmentally friendly maritime operations.