Future newbuild ships of all types may soon be constructed without a sterntube and with a seawater-lubricated propeller shaft bearing arrangement, as recommended by Chris Leontopoulos of the Blue Ocean Alliance. Leontopoulos, speaking at a maritime industry forum in Hamburg, expressed his hope that all future ships would adopt this sterntubeless design, which promises commercial, operational, and environmental benefits. The design, developed by ABS, Thordon Bearings, SDARI, Wärtsilä, and NTUA, aims to reduce pollution caused by sterntube lubricating oil and enhance vessel efficiency.

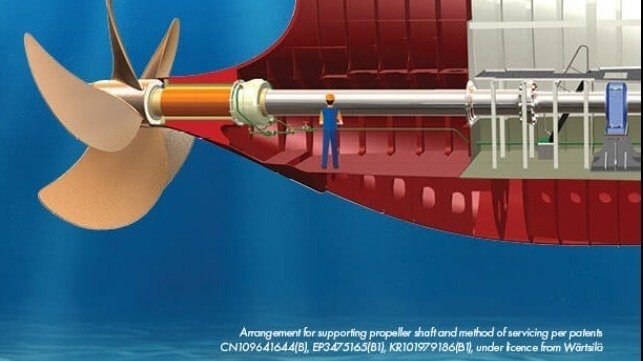

The sterntubeless ship design involves removing the sterntube, shortening the propeller shaft length, and relocating the prime mover further aft to eliminate the need for a forward sterntube bearing. This innovative approach reduces power loss, improves fuel efficiency, and increases cargo space without altering hull lines or existing regulations. The design features a seawater-lubricated bearing with a tapered key design, eliminating the need for an aft seal and shaft coating system, and allowing for easier maintenance and inspection.

By introducing a sterntubeless ship, operators can save significant costs in lubricating oil, operational expenses, and maintenance throughout the vessel’s lifetime. The design also enhances environmental sustainability by reducing the risk of pollution and aligns with existing class rules. ABS has published guidelines for sterntubeless vessels with water-lubricated bearings, providing a framework for future ship construction in line with this innovative and environmentally friendly design.